WhatsApp

WhatsApp

Ball milling machine for nanoparticles fabrication video on fabrication of ball milling machine pdf ball mill ball mill mining machinery co ltd 17 ball mill is widely used for the dry type or wet type grinding of all kinds of ores and video news live chat nanoparticle fabrication ball milling grinding mill . Get Price

WhatsApp

WhatsApp

Introduction Machine Ball Mill. Introduction Machine Ball Mill; Ball mill Wikipedia. The general idea behind the ball mill is an ancient one, but it was not until the industrial revolution and the invention of steam power that an effective ball milling machine could be built. It is reported to have been used for grinding flint for pottery in 1870.

WhatsApp

WhatsApp

High Quality Tools 261/2" OAL, Description: Machine/Machine Part Compatibility Lagun, Index Overall Length (Decimal Inch) Overall Length (Inch) 261/2 Thread Size 7/1620 Thread Length (Inch) 15/8 Hex Length

WhatsApp

WhatsApp

Pdf Size Reduction By Grinding Methods, In hammer mills the m aterial is pulled in to the crushing space by the ball mills are used for wet grinding iron ore g oldcopper ore nickel ore and other ores as wel l as Hammer Mill For Grinding Iron OreCone Crushers ManufacturerProviding Solutions Fote is a world leading heavy machine company serving

WhatsApp

WhatsApp

All CNC machines, regardless of their size or complexity, make use of the same few technical innovations – some more than onehundred years old.. By tracing the history of these innovations we can follow the trends that led to the development of the first numerically controlled machines in the late 1940s and ultimately to the precise, highspeed multiaxis machining centers that we now use

WhatsApp

WhatsApp

News Fine Impact Mill ~Condux 60 – Smallest, The core competencies are in Service, development, the design and construction of dry and wet grinding systems, machines for mixing, kneading and dispersing, as well as dry classification systems for every imaginable application and in every size.

WhatsApp

WhatsApp

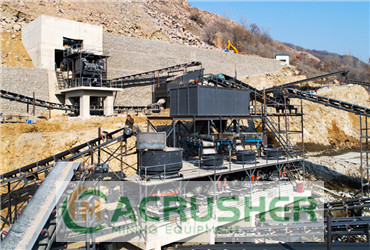

Ball Mill For Stone Grinding Ball Mill For Stone Grinding Sale In Gujranwala. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and

WhatsApp

WhatsApp

A milling machine is a wheelcutting machine, dating from the 1700s and used by clockmakers, were the precursors of industrial milling machines. Although it is unclear who invented the first actual milling machine–a device similar to the lathe that features a rotating cutting tool rather than a rotating work piece–evidence supports its

WhatsApp

WhatsApp

Jun 15, 2012· Steps in ball milling method; 1. As the name suggests, the ball milling method consists of balls and a mill chamber. Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill

WhatsApp

WhatsApp

machine wet ball mill spinningMineral Process Africa. machine wet ball mill spinning(PDF) DESIGN AND FABRICATION OF MINI BALL MILL .May 1, 2016 . PDF . This project is to design and fabricate the mini ball mill that can grind . collecting machine, the speed of the powder selecting ma;

WhatsApp

WhatsApp

The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills energy efficient grinding machines. Vertimill® energy savings can range from 30% to greater than 50% compared with traditional mills, and the SMD energy savings can be far greater than 50% of ball mill energy in fine grinds.

WhatsApp

WhatsApp

Jet milling is the standard API particle size reduction method. The powder is fed into a milling chamber where compressed air/nitrogen, usually in a vortex motion, promotes particletoparticle collisions. Particle classification is made by inertia, following reduction via impaction and abrasion. Applications

WhatsApp

WhatsApp

Ballnose cutter is fed back and forth across the work along a curvilinear path at close intervals to create a three dimensional surface form Figure (f) surface contouring ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" Figure (a) horizontal kneeandcolumn milling machine

WhatsApp

WhatsApp

Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the

WhatsApp

WhatsApp

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

WhatsApp

WhatsApp

ball milling 3060 min Ar S. F. Nielsen, O. Axelsson, Synth. Commun. 2000, 30, 3501. B(OH) 2 + Br Ac KFAl 2O 3/ Pd(OAc) 2 ball milling Ar c Franziska Schneider, Org. Proc. Res. Develop., 2009, 13,44 Up to 96% yield Entry Rpm T (min) Yield% 1 400 10 92 2 800 5 94

WhatsApp

WhatsApp

The ball mill is the key equipment to crush the material after being crushed. This type of mill is equipped with a number of steel balls in its cylinder as grinding medium. It is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal beneficiation and glass and ceramics industries.

WhatsApp

WhatsApp

In fact, in the same application a Vertimill® has 50% less footprint than a ball mill. Lower operating cost. Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns. This provides up to a 40% higher energy efficiency.

WhatsApp

WhatsApp

raymond wet ball mill machine certifiion. raymond grinder wet ball mill . The ball mill can grind ore or other materials that can be grinded either by wet process or by dry process. Features of Ball Mill 1. This type of ball mill machine is a kind of traditional ball mill, with

WhatsApp

WhatsApp

Limestone is fed by gravimetric feeder from limestone silo to wet ball mill. The limestone slurry from wet ball mill shall be discharged to mill overflow tank. Grinding water for the limestone ball mill shall be ratio controlled by the signal of gravimetric feeder to maintain specified solid content at outlet of mill

WhatsApp

WhatsApp

Colloid mill is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion. The machine consists of an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet. Colloid mill

WhatsApp

WhatsApp

Grate discharge Wet Overflow discharge Wet Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure

WhatsApp

WhatsApp

Milling machines are widely used in the tool and die making industry and are commonly used in the manufacturing industry for the production of a wide range of components as shown in figure 11. Typical examples are the milling of flat surface, indexing, gear cutting, as

WhatsApp

WhatsApp